- Home

Custom Seals

Custom Seal Solutions, On Demand

At HydraPak Seals, we deliver flexible, on-demand custom seal solutions for virtually any dimension or design. With a wide selection of profiles and materials, expert application engineering support, and efficient production processes, we minimize downtime and lost production while ensuring exceptional performance. Whether you need prototypes, small-batch production, or large-diameter seals, our fast turnaround and advanced manufacturing capabilities provide durable, high-quality seals tailored to your specific needs. From high-performance elastomers to advanced polymers, our materials are selected to meet demanding application requirements, ensuring reliability and cost-effectiveness every time.

High-Performance Products

Our custom-made seals are engineered to withstand challenging operating conditions, including high speeds, pressures, and temperatures. We understand that each application has unique requirements, and our team is dedicated to developing sealing solutions that provide reliable performance and extended service life.

We recognize the importance of minimizing downtime. Our efficient production system allows us to respond to your requests promptly, often within one hour, and deliver custom seals within 24 hours. This rapid turnaround is achieved without compromising the quality and precision of our products.

Choosing HydraPak Seals means partnering with a team committed to excellence in sealing technology. Our expertise, combined with a customer-centric approach, ensures that you receive solutions tailored to your specific needs. Whether it's for urgent repairs, maintenance, or custom-designed applications, we are here to provide the sealing solutions that keep your operations running smoothly.

Seal Configurator

Our Seal Configurator lets you easily create your own custom seal assembly by selecting your desired seal profile, material, and inputting dimensions. Once you've built your assembly, it's added directly to your cart for quick and hassle-free ordering. While most custom seals can be configured and priced instantly, more complex requirements may require you to reach out to our team for further assistance. For a fast, easy-to-use experience that’s both efficient and user-friendly, try the Seal Configurator today!

150+ seal profiles

30+ standard and specialty materials

Custom designs from drawings or samples

Cost-effective batch production

Prototyping support

No minimum order quantity

Rapid delivery

Material Solutions

Our material selection includes everything from high-performance elastomers to advanced polymers, ensuring that your seals can withstand the most challenging operating conditions. We offer options like polyurethane (TPU), PTFE, silicone, and nitrile, all designed to meet specific temperature, pressure, and chemical resistance requirements. Our application engineering team is available to provide expert guidance in choosing the right material for your project, ensuring optimal performance and cost-effectiveness.

At HydraPak Seals, we understand that selecting the right material is crucial for optimal seal performance and longevity. We offer a diverse range of high-quality materials to meet the specific demands of your applications:

Polyurethane (PU): Known for its exceptional wear resistance and high tensile strength, PU is ideal for dynamic applications requiring durability.

Nitrile Rubber (NBR): Offering excellent resistance to oils and fuels, NBR is suitable for a wide range of industrial applications.

Fluorocarbon Rubber (FKM): With superior heat and chemical resistance, FKM is perfect for high-temperature environments and exposure to aggressive fluids.

Ethylene Propylene Diene Monomer (EPDM): EPDM provides outstanding resistance to weathering, ozone, and water, making it suitable for outdoor and automotive applications.

Polytetrafluoroethylene (PTFE): Renowned for its low friction and excellent chemical resistance, PTFE is ideal for applications requiring minimal wear and high purity.

Our experienced team collaborates closely with you to determine the most appropriate material based on factors such as operating temperature, chemical exposure, pressure conditions, and dynamic requirements. This tailored approach ensures that each seal not only meets but exceeds performance expectations, providing reliable and efficient solutions for your specific needs.

Gaskets

HydraPak Seals provides high-quality gaskets tailored to meet the most demanding industrial applications. Using advanced water jet cutting technology, we deliver custom, prototype, and volume gasket solutions with exceptional precision. Our water jet system is fully programmable, eliminates the need for tooling, and is effective on nearly any material—metal, rubber, plastic, acrylic, and more. Because the water jet process produces no heat, your custom-designed gaskets are crafted without compromising material integrity.

Whether you need standard or custom gaskets, HydraPak Seals is your trusted partner. Our expertise in designing, engineering, and manufacturing precision gaskets ensures that we meet the needs of even the most challenging applications.

- Same-day Quoting: Fast turnaround times to exceed your expectations.

- Water Jet & Die Cutting: We produce gaskets in virtually any shape or pattern.

- Material Expertise: We stock a wide variety of materials in standard thicknesses, available by the square foot or yard.

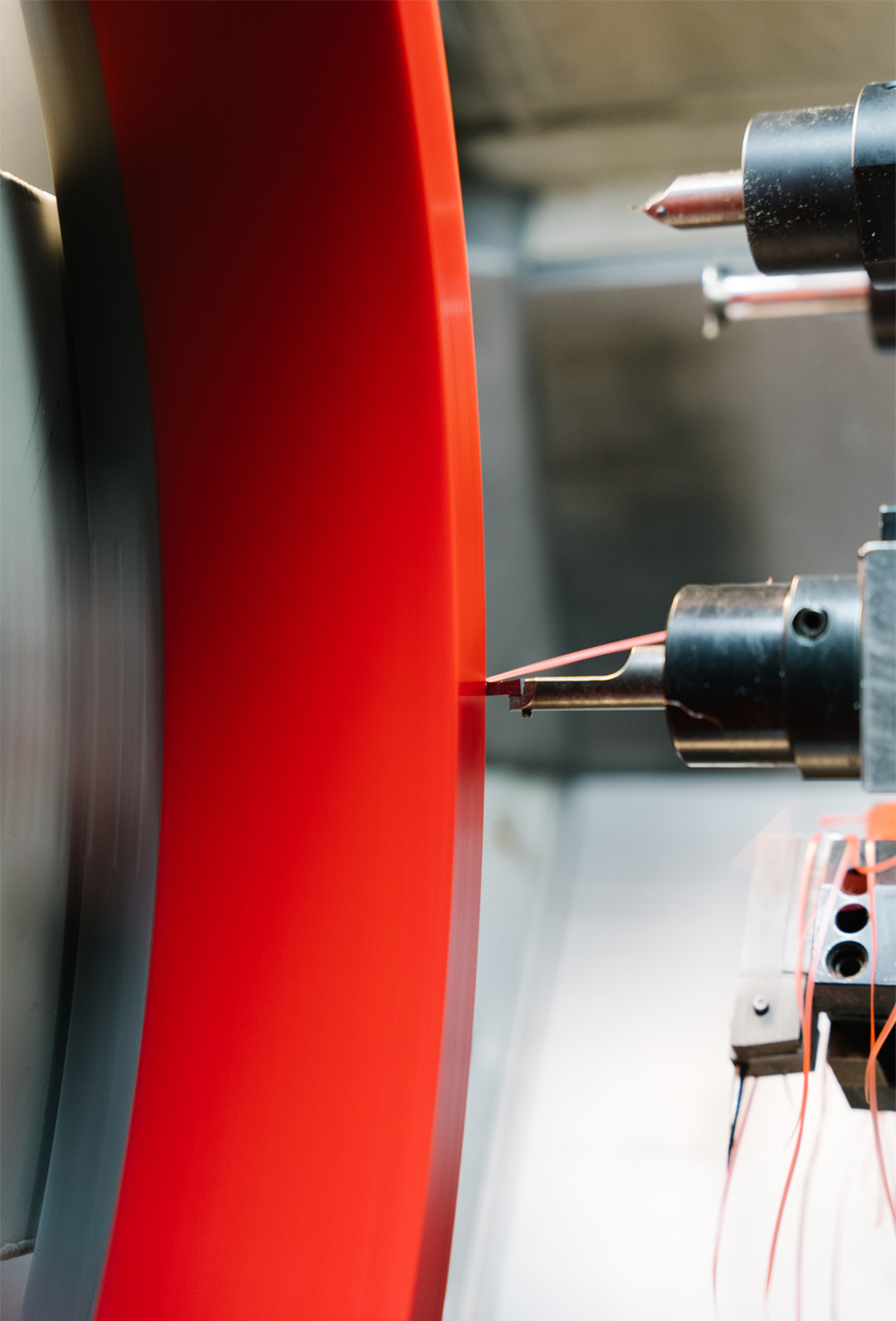

Spliced and Vulcanized O-Rings

At HydraPak Seals, we utilize advanced vulcanization technology to deliver high-quality seals and O-rings with large-diameter capabilities, tailored for your demanding applications. Vulcanizing is the ideal solution for non-standard sized seals, providing exceptional strength, stability, and precise tolerances.

Vulcanization is a specialized heating and molecular bonding process that fuses the ends of rubber profiles together using heat, adhesive, pressure, and time. This chemical bonding process creates a continuous seal with enhanced structural integrity. By crosslinking the polymer chains in rubber, vulcanization ensures the material can stretch under stress and return to its original form, resulting in seals that are stronger and more stable.

Our spliced and vulcanized O-rings are crafted from extruded cord stock, cut to length, and bonded to form a continuous seal. This approach eliminates the tooling costs and extended lead times associated with molded O-rings, making it a cost-effective and efficient solution for custom diameters and non-standard sizes.

Benefits of Spliced and Vulcanized O-Rings:

Ability to create large diameter profiles that cannot be molded.

High bond integrity with nearly undetectable joints.

Custom sealing applications with rapid production.

No tooling costs, reducing lead time.

Strong and stable seals for a wide range of uses.

Materials for Spliced and Vulcanized O-Rings:

Choosing the right material is crucial for ensuring durability and performance. HydraPak offers a variety of compounds, including:

Buna

Viton™

Silicone

EPDM

Neoprene

Our technical team provides personalized support to analyze your specific needs and recommend the most accurate and cost-effective material for your application.

Precision and Quality Assurance

From design and prototyping to production, our engineering team ensures every spliced and vulcanized O-ring meets HydraPak’s exacting standards. Each O-ring undergoes a thorough visual inspection to guarantee a consistent, high-quality product.

Best vulcanized bond on the market at competitive prices.

Dimensional and material validation available upon request.

Expertise in custom, large-diameter, and non-standard seals.

Rapid turnaround to minimize downtime.

When you need durable, precision-engineered vulcanized seals, HydraPak Seals is the trusted partner for reliable performance. Contact us today to discuss your application requirements.

HydraPak Seals is your trusted partner for innovative sealing solutions. Contact us today to discuss your custom seal requirements and discover how we can help optimize the performance and efficiency of your operations.